Original Clear-Strates™ from a Trusted Manufacturing Company

QQOA is the original manufacturer of Clear-Strates. Our fiber support products are superior to other substrates on the market because of our manufacturing processes using quartz with exceptional grade.

Machined vs. Fused

Clear-Strates are smooth and fused in contrast with other machined products in the industry. Anytime a glass, such as quartz, is scored or machined, it creates a stress point in the material. Therefore, a machined substrate will have many stress points. This makes it prone to breakage, whether caused by handling or expansion and contraction of epoxies affixed onto the groove area.

Our Clear-Strates virtually eliminates the risk and concern of breakage, which is especially crucial once completely assembled into a passive component. Since replacing a finished component can be costly, Clear-Strates is your best choice for a substrate.

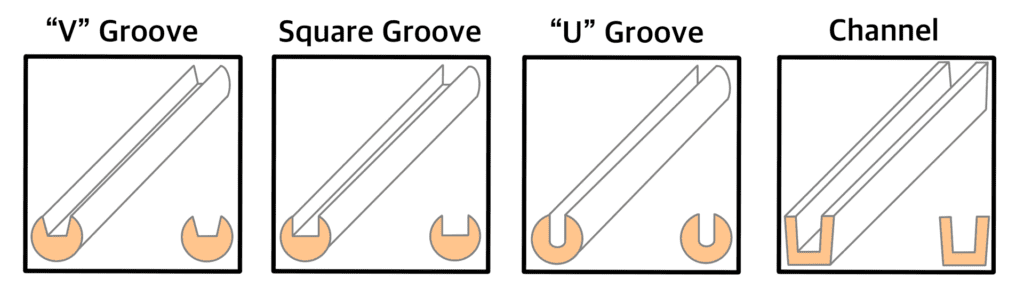

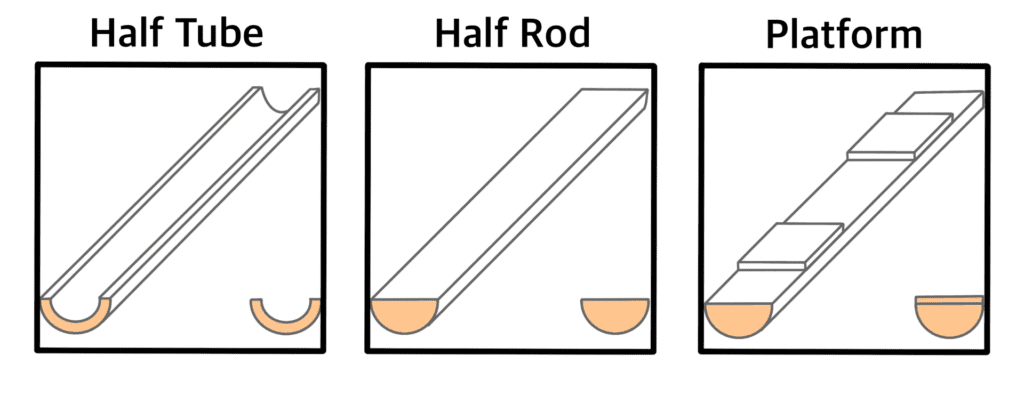

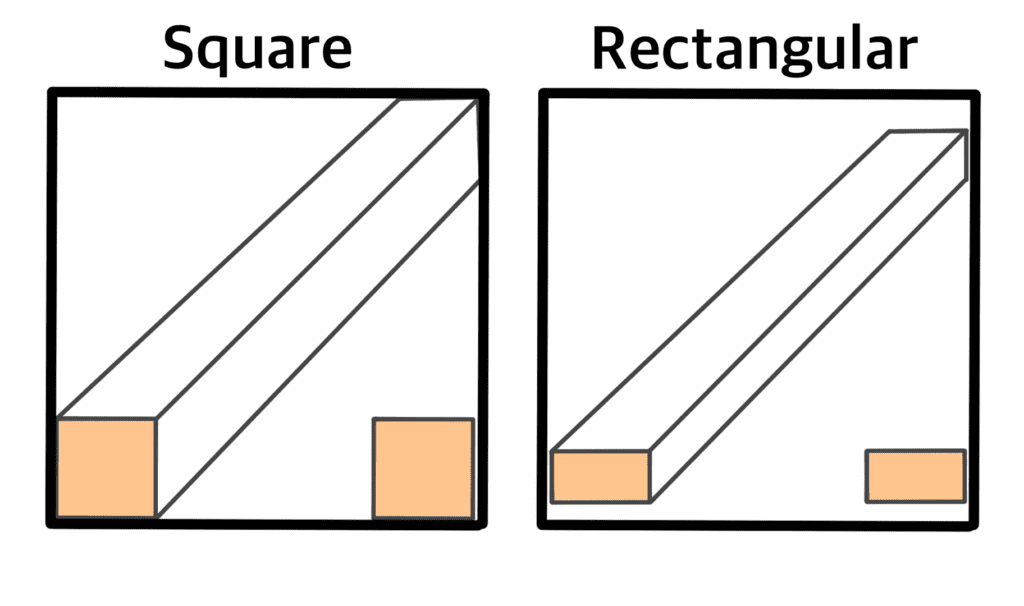

The following illustrations demonstrate some typical Clear-Strates designs, which can be manufactured to your specifications. Special, custom designs and tight tolerances are also available. Simply send us a print or drawing for a prompt quotation or contact us for more information.

Typical Tolerances:

OD +/-0.10 mm

Size Ranges:

1.00 mm to 3.50 mm OD and W

Typical Tolerances:

OD +/-0.10 mm

Size Ranges:

<1.00 mm to 8.00 mm ODs

Typical Tolerances:

W +/-0.10 mm

Size Ranges (Square):

1.00 mm x 1.00 mm

Size Ranges (Rectangle):

1.00 mm TK x 2.00 mm W

Material

QQOA uses special, high-grade QQ 319 fused quartz, which offers impressive inherent qualities such as durability, dimensional stability, and structural integrity. Because of this, it has become the material of choice for fiber support products.

Properties of Preference and Performance

QQ 319 fused quartz demonstrates the most favorable properties compared to other common industrial materials. Perhaps one of the most important is its extremely low coefficient of expansion. This makes the material particularly useful in critical fiber optic applications requiring a minimum sensitivity to thermal changes.

As indicated above, QQ 319 fused quartz offers the lowest coefficient of thermal expansion and index of refraction. Its properties also match the closest to that of the optical fiber itself. When determining which fused fiber support to use, Clear-Strates is the clear choice.

Material Handling

QQ 319 fused quartz requires proper handling and storage to maintain the material’s innate qualities. Our Clear-Strates are cleaned and carefully packed at the factory and should always be kept covered in their original container until ready for use. They should always be protected from dirt and moisture, which could affect their purity and performance.

Clear-Strates should always be handled with clean, white cotton gloves and never latex gloves. Additionally, human hands should never handle them since oils and sodium in the skin will contaminate the material.

Cleaning Procedure

If Clear-Strates needs to be re-cleaned, we recommend using the following procedure. Remember to be careful when handling parts since the ends may chip if hit up against a hard surface.

- Gently place parts into a stainless-steel pot.

- Fill the pot with deionized or distilled water to about 1” over the pieces and add a small amount of mild degreasing agent.

- Place the pot on a burner with medium heat.

- Bring it to a medium boil, then remove it from the burner.

- Rinse the parts thoroughly, several times, with deionized or distilled water.

- Dry them in an oven at 200°F or rinse the parts in 100% acetone and let them air dry.